In today’s fast-paced manufacturing and logistics environments, efficient and reliable packaging solutions are more critical than ever. One innovative technology that has gained significant attention in recent years is the Stretch Hooder. But what exactly is a stretch hooder, and how can it transform your packaging process?

This article will explore the basics of stretch hooding technology, its benefits, and how industry leaders like Dostar Packing Equipment Co., Ltd are helping businesses upgrade their packaging lines with advanced automation.

What Is a Stretch Hooder?

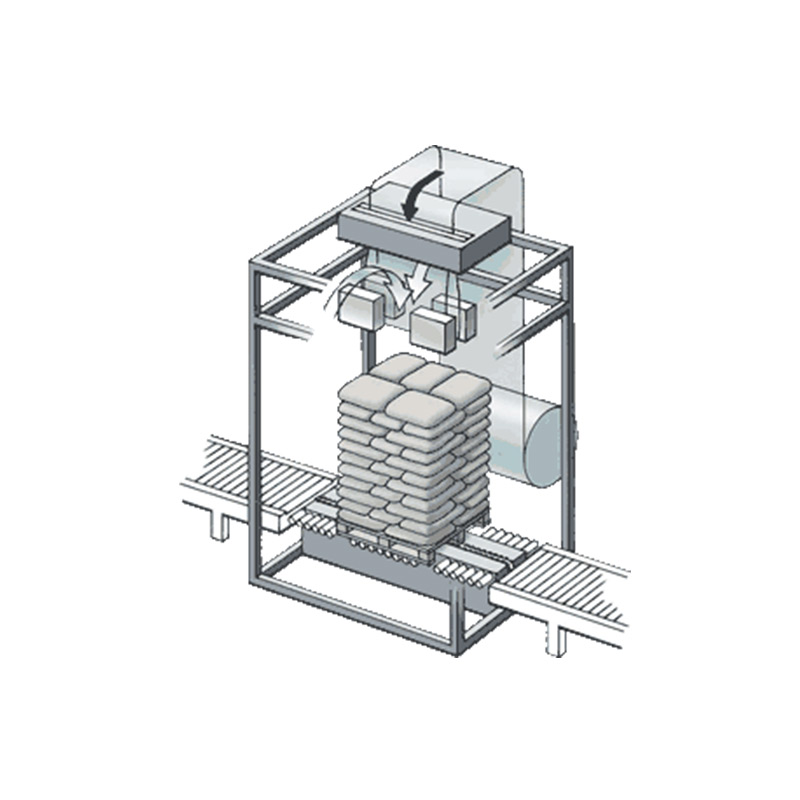

A Stretch Hooder is a specialized packaging machine designed to wrap products—usually palletized goods—with a highly stretchable hood film. Unlike traditional shrink wrapping, which uses heat to secure the film, stretch hooding relies on the elastic properties of the film stretched over the load to form a tight, protective cover.

The stretch hooder pulls a tubular film over the top of a pallet, stretching it to conform tightly around the load. This method offers excellent load stability, weather protection, and reduces film usage compared to conventional packaging methods.

How Does a Stretch Hooder Work?

The stretch hooding process typically involves several key steps:

-

Film Feeding: The machine feeds a tubular hood film from a roll, preparing it to be placed over the product.

-

Stretching: Using specialized clamps and mechanical arms, the film is stretched vertically and horizontally.

-

Hood Application: The stretched film is then pulled down over the palletized load, conforming tightly to its shape.

-

Sealing and Cutting: The film is sealed and cut to form a protective hood that stays firmly in place without requiring heat.

How Does a Stretch Hooder Improve Packaging Efficiency?

1. Reduced Film Usage

Stretch hood films are designed to stretch significantly, allowing the same amount of film to cover larger loads. This leads to lower material costs and less waste.

2. Faster Packaging Speeds

Stretch hooders operate quickly and reliably, enabling high throughput rates on packaging lines. This speeds up pallet preparation and reduces labor costs.

3. Improved Load Stability and Protection

The tight fit of the stretched hood stabilizes products on the pallet, minimizing movement during transit. It also offers excellent protection against dust, moisture, and weather, preserving product quality.

4. Energy Efficiency

Since stretch hooding does not rely on heat for sealing, it consumes less energy compared to shrink wrapping systems, contributing to lower operational costs.

5. Versatility

Stretch hooders can handle a wide variety of pallet sizes and shapes, making them ideal for industries ranging from food and beverage to construction materials.

Dostar Packing Equipment Co., Ltd: Innovating Packaging Automation

For companies seeking to upgrade their packaging lines with state-of-the-art stretch hooding technology, Dostar Packing Equipment Co., Ltd offers comprehensive solutions. As a high-tech enterprise specializing in the research, integration, manufacturing, sales, and service of automated packaging lines, Dostar is committed to delivering both semi-automatic and fully automatic packaging systems tailored to customer needs.

Their expertise includes the design and production of stretch hooders that maximize efficiency and reliability, helping businesses reduce costs while improving packaging quality and speed.

Final Thoughts

A Stretch Hooder represents a smart investment for manufacturers and logistics providers looking to enhance packaging efficiency, reduce material consumption, and protect products better. By understanding the technology and partnering with experienced providers like Dostar Packing Equipment Co., Ltd, businesses can stay competitive in a demanding global market.

If you're considering upgrading your packaging line, exploring stretch hooding technology could be the game-changer your operation needs.

www.dostar-pack.com

Dostar Packing Equipment (Wuxi) Co., Ltd