Frame welding is an essential part of many industrial sectors, including mining, construction machinery, material handling, energy, and heavy-duty transport equipment. Choosing a professional welding service provider can have a significant impact on the structural integrity, operational safety, and cost efficiency of your entire project. Companies like Hengli, with full-process capabilities from cutting and machining to welding and surface treatment, demonstrate how comprehensive expertise can add tangible value to customers.

Here are the seven key advantages of working with a professional frame welding partner:

1. Consistent Structural Strength

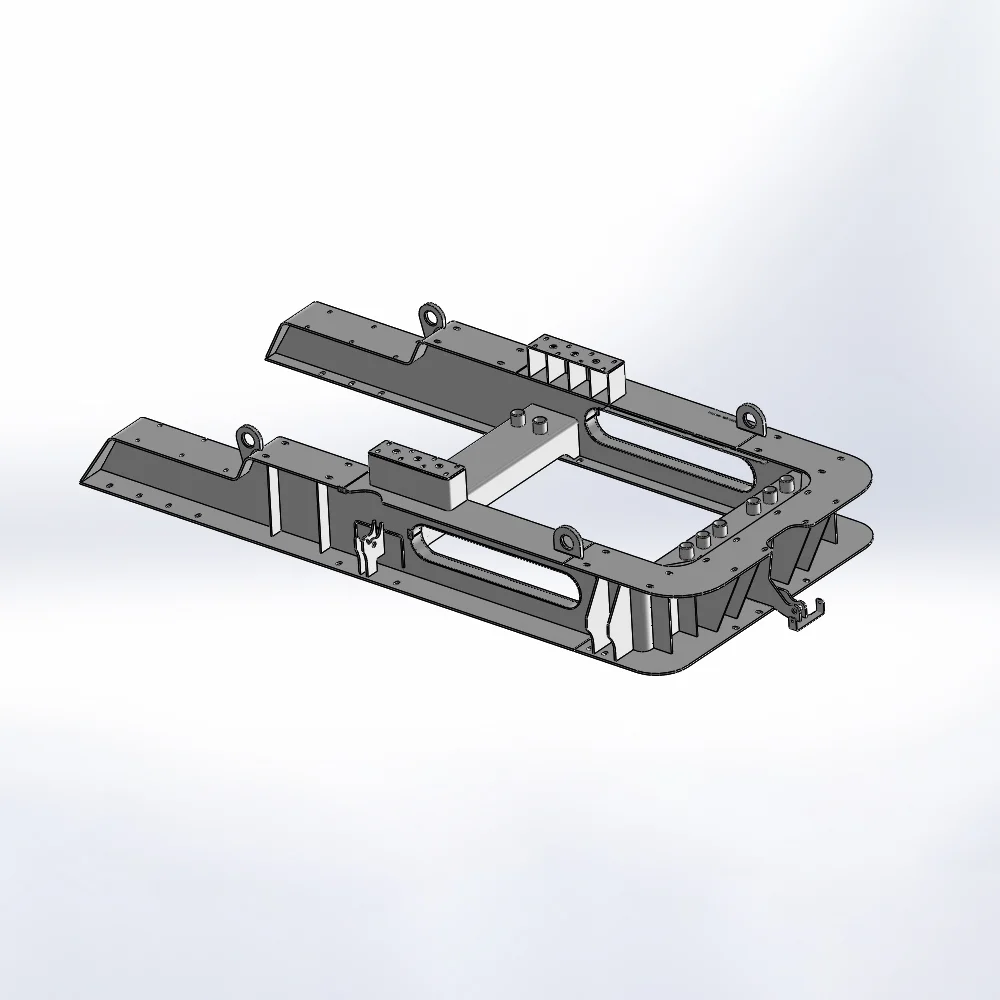

High-quality welding ensures that each joint achieves the designed mechanical strength, which is crucial for heavy-load-bearing equipment such as excavators, loaders, or port machinery. Professional welders follow strict procedures and inspection standards, minimizing failure risks under high-stress working conditions.

2. Precision and Dimensional Accuracy

Frame components often require tight tolerances to fit into complex assemblies. Professional welding services use CNC machining, jigs, and automated systems to maintain precise alignment during welding. This ensures that the finished product meets design specifications and integrates seamlessly with other parts.

3. Access to Advanced Equipment and Processes

Leading service providers invest in robotic arms, positioners, longitudinal seam welders, and automatic gantry systems, which improve efficiency and reduce manual errors. Hengli, for instance, utilizes both automated and semi-automated welding lines, allowing for stable production of medium to large structures.

4. Integrated Manufacturing Capabilities

A major benefit of working with a full-service supplier is process integration—from cutting, bending, and welding to surface blasting, painting, and final assembly. This reduces handover errors, shortens lead times, and lowers your total production cost.

5. Certified Quality Assurance

Professional welding companies typically have quality certifications such as ISO 3834, AWS D1.1, or EN 1090. They perform non-destructive testing (NDT) like ultrasonic or magnetic particle inspection, and maintain traceable quality records. At Hengli, all welding joints are inspected according to customer standards, with detailed reports provided for each batch.

6. Customized Solutions for Diverse Applications

Industrial applications often involve unique technical challenges. A professional supplier can offer tailored welding solutions—whether it’s for mining frames, high-torque machinery, or lightweight transport modules. Their engineering support helps optimize your design for manufacturability, durability, and cost-efficiency.

7. Reliable Delivery and Long-Term Partnership

Large-scale industrial projects require on-time delivery and consistent quality. Professional providers offer capacity planning, project tracking, and flexible scheduling, which help customers keep production on track. Hengli's multi-workshop system and lean manufacturing model enable timely responses to urgent or large-volume orders.

Conclusion

Whether you’re manufacturing construction equipment, energy systems, or heavy industrial machines, choosing a professional frame welding service is not just about outsourcing a process—it's about enhancing the quality and reliability of your entire product. With a supplier like Hengli, you gain not only technical expertise but also a partner committed to your long-term success.

www.hlmetal.net

HENGLI